BEST CRAFT BREWS WITH PRODEB:

Prodeb is the largest and most advance microbrewery equipment manufacturer in India, using latest belgian technology. It is a part of the Canadian Crystalline group which has been providing equipment and solutions to the brewing industry for over 50 years.

Prodeb has been providing turnkey microbrewery system solution throughout the world for the last decade. It is the first Indian manufacturer of microbrewery equipments with european technology.

Prodeb with its advance know-how and state of art technology has been providing craft brewery system throughout the world with tailored solution to the individual brewer's needs, there by optimizing efficiency and brewing experience. Prodeb manufactures in-house the total line of microbrewery equipment which includes malt mill, brew house fermenters and bright beer tanks.

Apart from the above all accessories (i.e.) Ice Water Tank, Glycol Tank, Hot liquor Tank, CIP System and Refrigeration chillers are also manufactured in its 50,000 square meter facility in chennai india.

Prodeb offers a wide spectrum of services which includes detail engineering ( Brewery layout, 3D modeling,3D piping electrical and instrumentation drawings)Prodeb also manufactures and installs process water treatment equipment brewing water equipment to support the brewing process with the purest low Tds water, as well as fortified water to produce classic styles of beer. Our water treatment can be adjusted to mock any parameter of water worldwide.

Prodeb provides compact effluent treatment Systems to treat microbrewery waste water. The treated water could be used for various purposes.

EXPERIENCE AND EXPERTISE – GUARENTEES YOUR SUCCESS:

Prodeb over the last decade has supplied microbrewery solution from 1HL up to 100 HL.

Canadian Crystalline which is the part of the prodeb group has established more than 200 large scale breweries and distilleries over the last 40 years for leading brands example to name of few : M/s. UB Limited (King fisher, Kalyani), M/s. SAB Miller Ltd (Fosters, Royal Challenge, Castle, haywards 5000, Miller,Peroni Nastro Azzurro) M/s. Mysore Breweries Ltd (Knock out), M/s. Mohan Breweries and Distilleries Ltd (Golden eagle) with its JV Technology partner M/s. RITA Bottling.

Prodeb brewery has executed more than 100 microbreweries world wide in Australia, Europe, Africa, USA, Canada and South America. In India prodeb brewery has more than 20 completed microbrewery and more than 60 microbrewery getting installed within the current year

KEEPING OUR CLIENT AHEAD OF COMPETITION:

Through collaboration with universities and experienced Brew Masters from Europe, America and Australia. Prodeb has unleashed the most advanced line of brewery equipment which ensures minimum energy and maximum efficiency and extraction during the brewing process(Prodeb has achived 96% extractor). The In-house path breaking technology of soft/gentle boil and our negative cO2 breweries are being Installed world wide, thereby saving cost and protecting the environment in the process.

SELL MORE BEER WITH PRODEB:

Only prodeb brewery projects in india sell more than 20,000-30,000 liters of beer per month.

Prodeb is also the exclusive equipment provider and brewing technology partner for 22 numbers of PLAYBOY Beer Garden throughout India. The first one has opened in Pune.

Prodeb has recently launched the largest microbrewery in India (Bangalore) with production capacity of 30,000 Liters of Beer per month in DRUDE GARDEN which is 32,000 square feet microbrewery pub and restaurant.

Prodeb has also executed the second largest brewery in India BIG BREWSKY with a capacity of 28,000 Liters of Beer per month. BIG BREWSKY- Sarjapur is spread over 25,000 square feet.

Currently Prodeb is building the largest Mega Micro Brewery in the world. BIG BREWSKY – HENNUR Spread over the 70,000 square feet with a brewing capacity of 50,000 liters of beer per month.

Prodeb has established 9 out of 12 microbreweries in hyderabad with the first microbrewery of Hyderabad being PROST, with the capacity of 25,000 liters of beer per month spread over 18,000 square feet followed by HEARTCUP in Jubilee Hills and Kondapur with a capacity of 25,000 Liters/month and Hope Floats in Jubilee Hills with a capacity of 20,000 Liters per month.

Prodeb has also built the first Microbrewery in Calcutta COUNTRY ROADS with the capacity of 15,000 Liters per month.

BEST BREW MASTER SUPPORT FROM PRODEB:

Prodeb believes that to offer the best beer experience, the brewer is as important as the equipment and raw material. A great tasting beer can only be delivered by evolved brew master.

Prodeb has a bunch of the best Brewers from Europe, Australia, Canada and USA.

Prodeb, provides these Brewers at a nominal fee.This is the reason Prodeb clients sell the highest quantity of beer compare to any other outlets.

ENHANCING BEER EXPERIENCE-KEEPING THE BEER TRADITION AND CULTURE ALIVE:

As the market leader in India in the Brewpub / Restaurant brewery space, Prodeb understands the fine line between product quality and creating a great looking Ambience. Our brewery equipment meet the highest aesthetic requirement. Whether a vintage or contemporary look stainless steel or copper or even the latest titanium range, every single part of the brewing equipment sparkles. Our brewery makes a statement Like a show stopper. To make things spotlessly perfect we install every client Brewery according to their interior design scheme.

Whether traditional of craft beer, a nostalgic look or a exclusive design – remind your guest why beer culture still thrives today. They will appreciate you for your Effort.

MALT MILL

The machine is a pair of roller grinder whose product is rough smashed malt. Its main gadget is its two cylindrical drums with the same diameter. The two drums rotate in opposite directions for generating extruding force and shearing force to smash malt. There are waves / grooves on the drum surface. The malt is sent in the gap between the drums. The opening between the drums can be adjusted according to smashing requirement and size of broken malt grain required for the brewing purpose. |

|

Malt Mill |

|

MASH AND BOILING TANK

It is used for soaking malt, mashing and boiling wort. The stainless

steel product profile is ornamented by red / yellow copper plate

and heat is preserved by special insulation material. Main components

are composed of rake mixer, heater system and Geared motor, and

equipped with temperature controller and wort cooler, which completes

the whole saccharification process. Mash and Boiling TankS are

provided with option of top mixing and bottom mixing according

to mixing form and steam inter layer heating and electric heating

according to heating form.

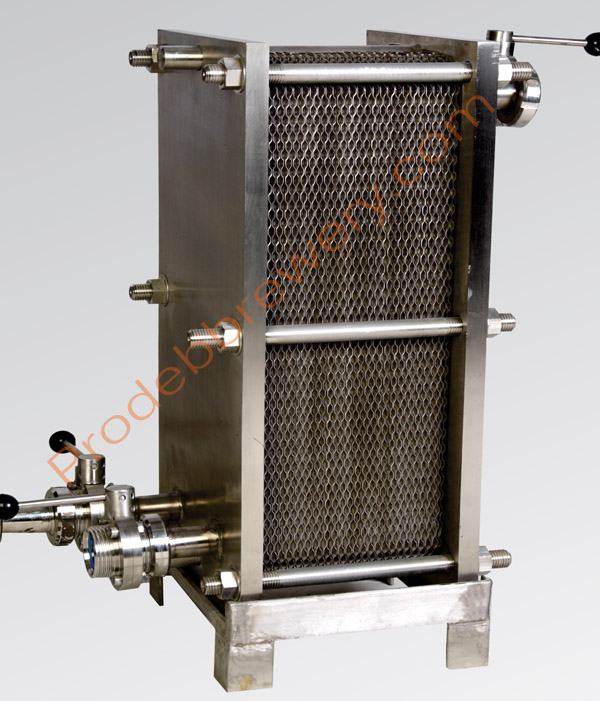

FILTER / WHIRLPOOL TANK :

The stainless steel (SS 304) product profile is ornamented by

red/ yellow copper plate and heat is preserved by special insulation

material.

It is composed of upper part and lower part. The upper part

is Filter Tank (i.e.,) Lauter Tank which is used for separating

suspended solid from the liquid, Wort and the lower part is temporary

storage of Wort as well as a whirlpool which is used for separating

coarse sludge, protein solid, hops from the wort. |

|

Mash Boiling Tank |

|

Mash Boiling Tank |

|